Tactical fiber optic cables

The term "tactical" is the designation of a special category of cables intended for demanding operating conditions and very high requirements are placed on them in terms of durability and reliability. They are primarily intended for military data and communication applications. However, it is also possible to use these cables in civil applications, for example in camera systems. The high flexibility of these cables allows them to be used multiple times in the sense of repeated unwinding and rewinding. Therefore, for these cables to meet the demanding requirements, special materials and specific production processes must be used in their production. The load when testing these cables is significantly higher compared to commonly used optical cables. The cable sheath is made of thermoplastic polyurethane. A typical feature of this material is its high resistance to water, UV radiation, chemicals, microorganisms, and mold. It also significantly exceeds commonly used materials in terms of mechanical resistance and is tough, being especially resistant to being cut by a sharp object or punctured. The most striking feature is its high flexibility, which remains unchanged even at very low temperatures The secondary protection of the fiber is made of highly mechanically, chemically, and thermally resistant Polyamide 12, which protects the optical fiber from mechanical damage. Kevlar tensile elements give the cable high tensile strength and protect optical fibers from damage during unwinding and winding. The durability of the "Military" cable is visible when comparing the properties with a standard optical cable of similar construction:

|

|

Military cable |

Standard cable |

|

Operating temperature range |

-55 °C to +85 °C |

-20 °C to +60 °C |

|

Compressive strength without change in attenuation |

5000 N |

~1500 N |

|

Compressive strength with reversible damping |

9500 N |

~2000 N |

|

Impact resistance |

20 Nm |

~5 Nm |

|

Flexibility |

100 N, >15 000 cycles |

20 N, 100 cycles |

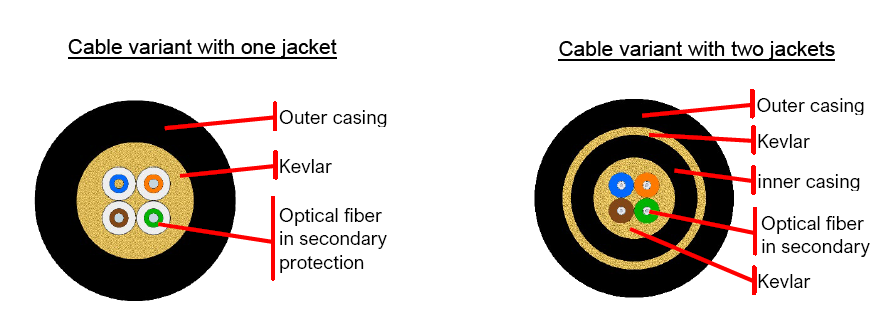

In addition to the standard cable construction, a variant with a second sheath is also available to further increase cable resistance.

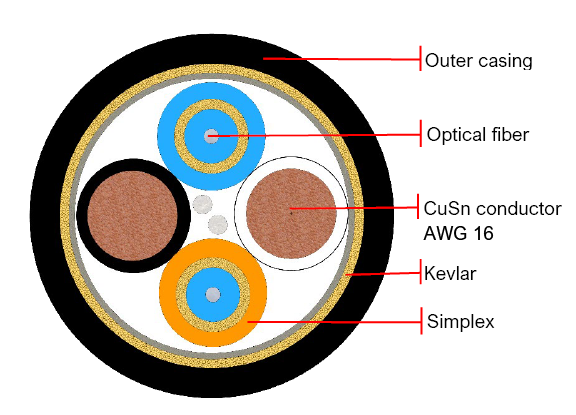

OPTOKON provides the complete solution for applications where optical fiber is brought to the antenna (FTTA) and for security CCTV applications. The systems enable data communication via optical fibers and by using copper wires, power can be used in places where it is not usually available or where installation is too expensive. Two cables are thus combined in one – for data transmission and powering various devices. This means that savings on material and installation time can be achieved by installing one cable instead of two.

The cable can be used for permanent and temporary installation; the structure is designed for multiple unfolding and coiling.

The hybrid cable contains two simplexes with SM or MM optical fiber in a tight secondary shield and 2 x 16 AWG tinned copper wires with FEP (Fluoroethylene Propylene) insulation. The inside of the cable is protected against penetration of moisture by water-swelling materials. The cable sheath is made of polyurethane, which gives the cable high flexibility and mechanical resistance.

|

Cable tensile strength |

500 N |

|

Operating temperature range |

-40°C to +70°C |

|

Compressive strength |

1500 N/10 cm |

|

Test voltage of conductors underwater |

2000 V for 1 hour at 20°C |

Michal Velc, Head of Fiber Optic Cable R&D Center, OPTOKON Kable Co., Ltd., s.r.o.