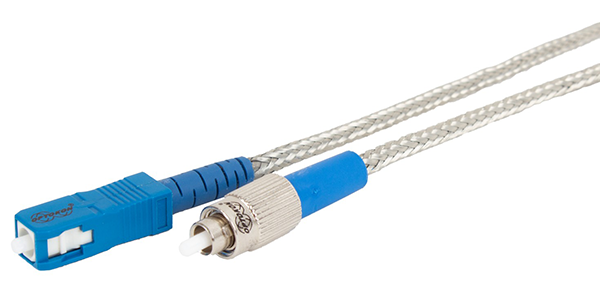

EMI Cable Shielding and Protection Solution

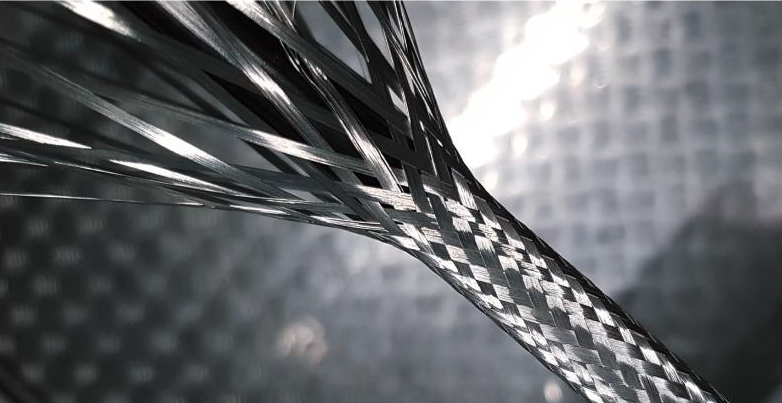

Increase the mechanical protection of the fiber optic cables and patchcords to prevent damage to the cable during installation or subsequent installation with additional shielding by braiding the outer sheath of the cable. Increase cyber protection during installation and handling of the cable when transmitting sensitive data in the information security field.