Cable for external installation by air-blowing technique

|

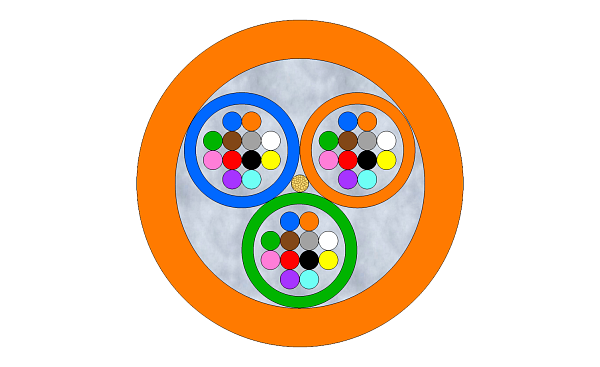

Number of Fibres |

36 |

|

|

Number of fibres in tube |

12 |

|

|

Number of tubes |

3 |

|

|

Nominal outer diameter (mm) |

3.4 |

|

|

Calc. cable weight (kg/km) |

11 |

|

|

Short-term tensile strength (N) |

70 |

IEC 60794-1-101 |

|

Long-term tensile strength (N) |

20 |

IEC 60794-1-101 |

|

Crush resistance (N/100 mm) |

500 |

IEC 60794-1-103 |

|

Max. impact loading (Nm) |

3 |

IEC 60794-1-104 |

|

Min. bend radius not load (mm) |

50 |

IEC 60794-1-111 |

|

Min. bend radius load (mm) |

65 |

IEC 60794-1-111 |

|

Operating temperature range (°C) |

-15 to +70 |

IEC 60794-1-201 |

|

Storage temperature range (°C) |

-30 to +70 |

IEC 60794-1-201 |

|

Installation temperature range (°C) |

-10 to +50 |

IEC 60794-1-201 |

|

Class of fire reaction |

Fca |

EN 50575, EN 13501-6 |

|

Fibre Type |

G.657.A1 200µm, G.657.A2 200µm |

|

Fibre colour |

Blue, Orange, Green, Brown, Grey, White, Red, Black, Yellow, Violet, Pink, Aqua |

|

Tube colour |

Blue, Orange, Green |

|

Strength member |

Aramid yarn |

|

Core filling compound |

Low-viscosity filling compound |

|

Jacket material |

Low Friction Plastic |

|

Nominal jacket thickness |

0.4 mm |

|

|

|

|

Attenuation @Wavelength |

1310 nm |

1550 nm |

1625 nm |

|

|

Typical Attenuation |

0.33 |

0.23 |

0.24 |

|

|

Maximum Attenuation |

0.38 |

0.28 |

0.35 |

|

|

Typical attenuation is the value measured for at least 90% of the fibres in the cable. |

||||

|

Number of Fibers |

Cable Code (Ordering Code) |

Delivery length |

Packing |

|

36 |

OPK-O-MTFFM-36(3x1.2)LTAB-200A1-xx |

2100 m ± 5% , 4200 m ± 5% |

Plywood reel |

|

xx – jacket color (see Cable code datasheet) |

|||